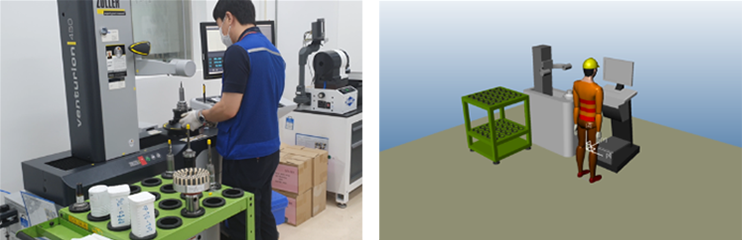

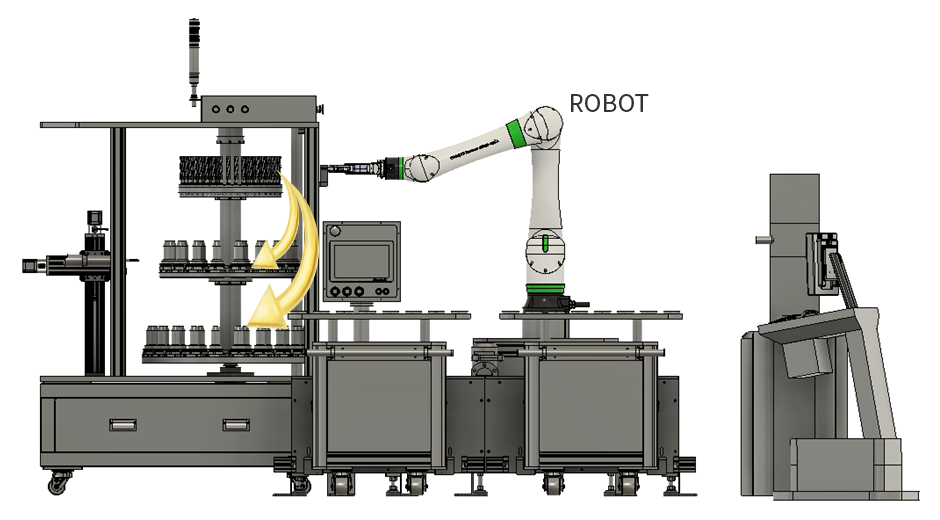

We are designing the process that the customer wants and establishing

Collaborative Robotic System through optimized investment with

considerations for efficiency in comparison to the

existing process by using

Cyber Physical System.

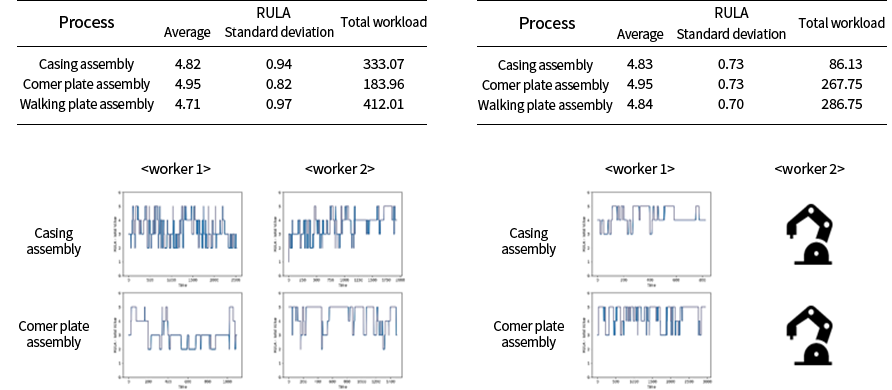

32% reduction in worker workload 20% improvement in job smoothness

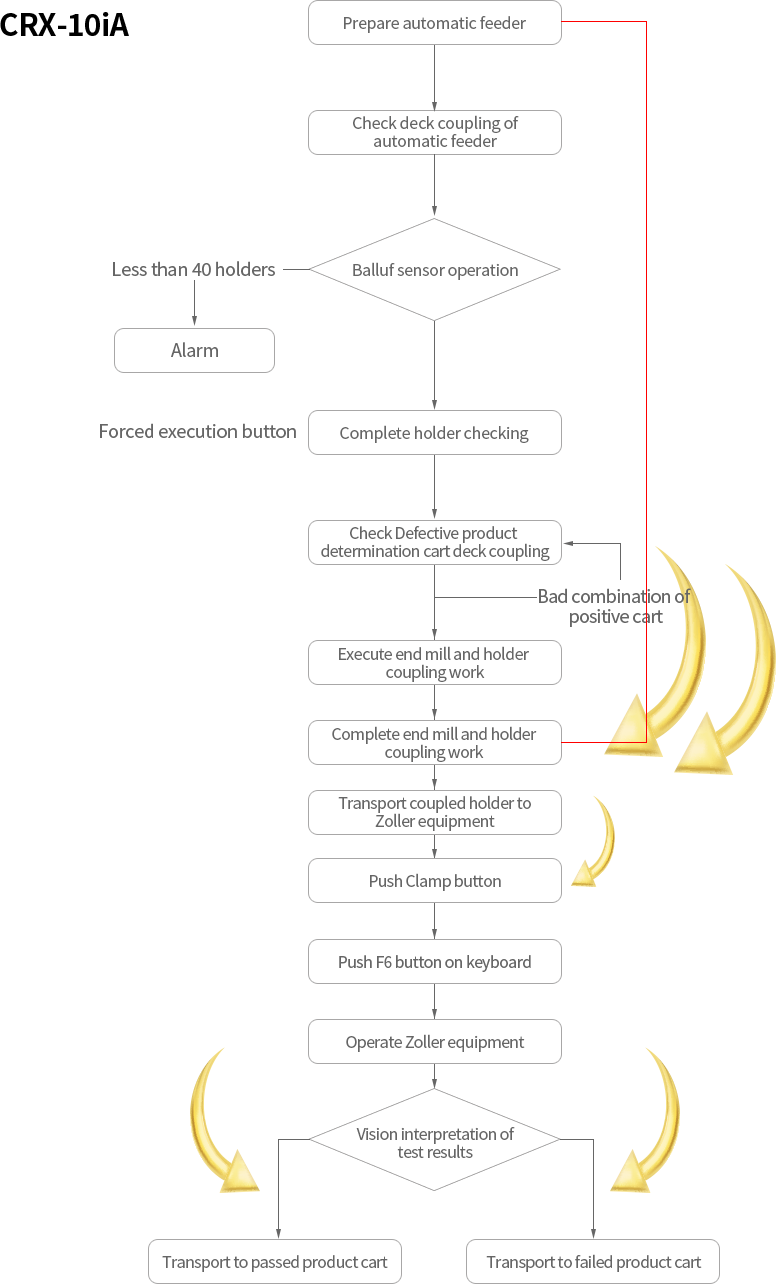

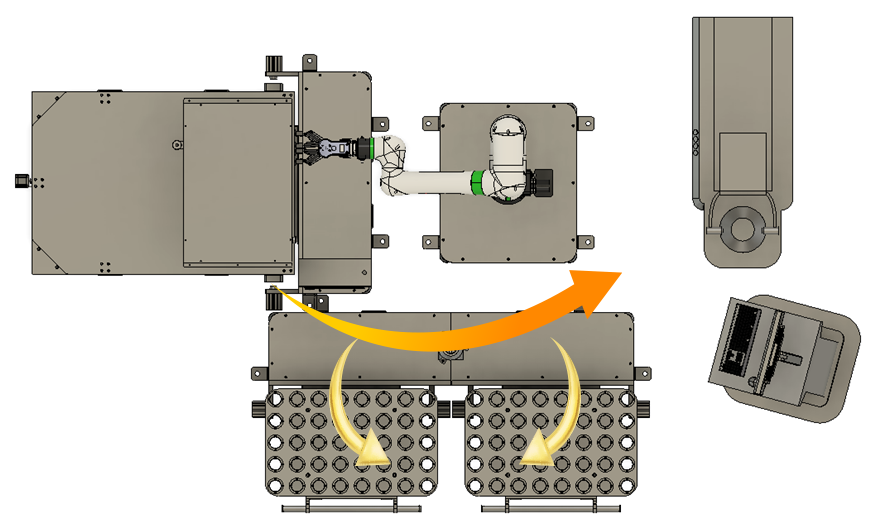

Distinguish end mill and holder by using feeder > Unite through feeder > Transport through robot >

Inspection with inspection device > Classification into passed and failed products

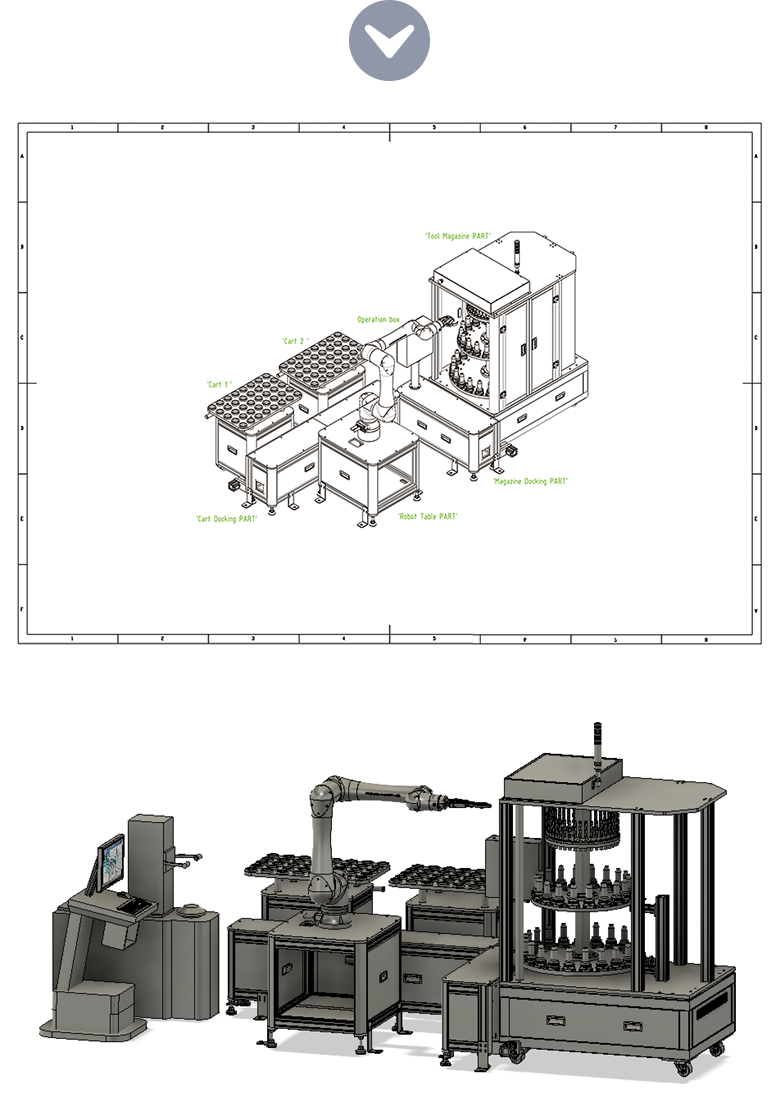

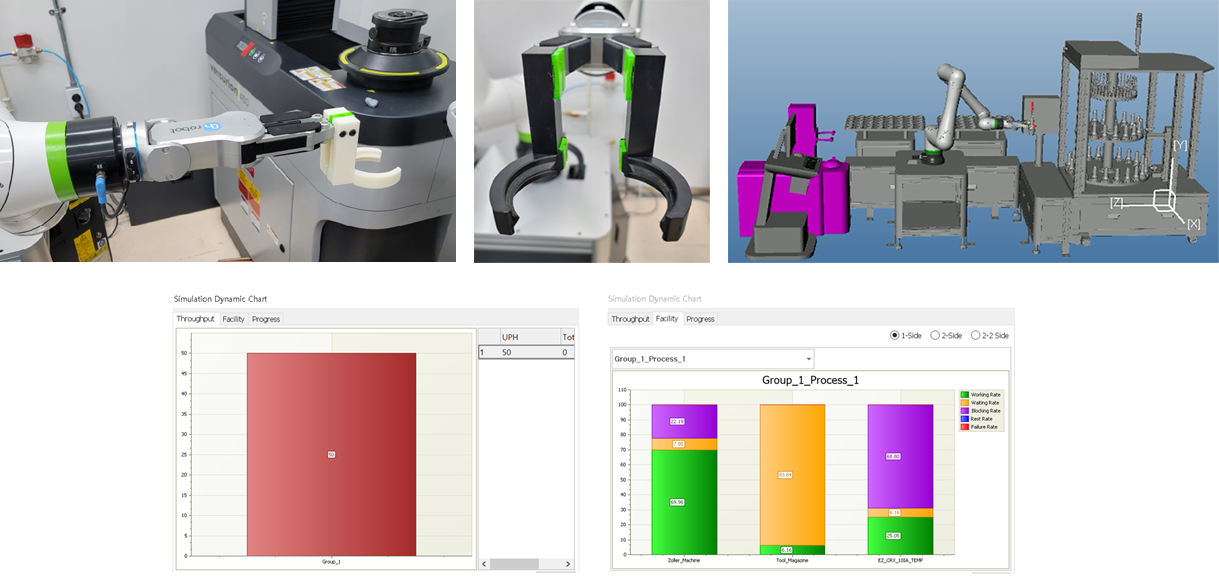

Produce gripper through 3D printing and modification work with optimized design through

diversified movements > Executed with CNC processed product.

Execute simulation of arrangement and movement of equipment and robot through CPS >

Execute optimization of the arrangement of equipment and movement of robot